PRODUCTS

HOME > PRODUCTS

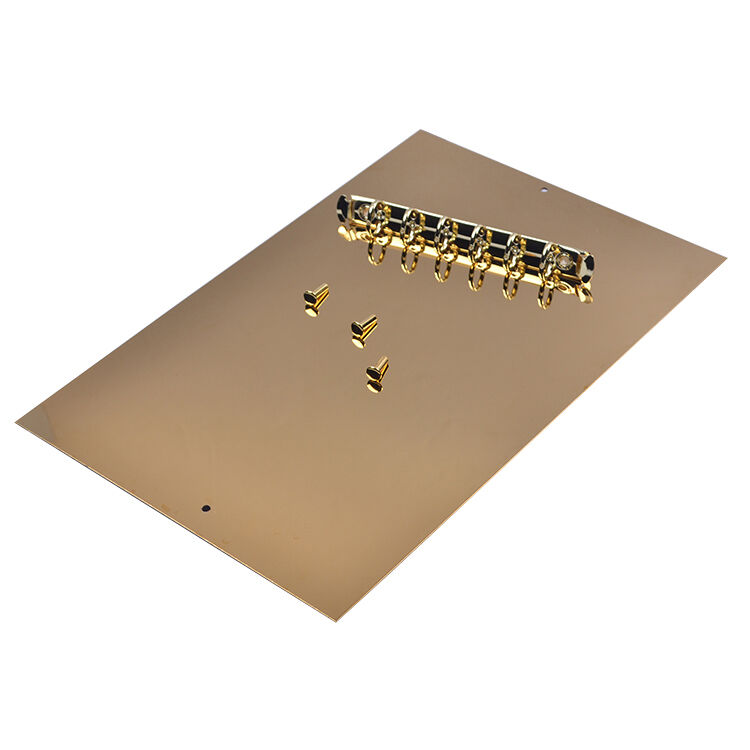

One of the most popular grades 316L for #8 Mirror Sheet

316L stainless steel sheet #8 mirror has a non-directional finish that virtually looks like a mirror. 316L stainless steel sheet #8 mirror possesses a highly polished finish and does not contain or have a coating or finishing material to give it reflectivity. 316L stainless steel sheet #8 mirror comes with a double layer of PVC film to protect the mirror finish during fabrication and installation.

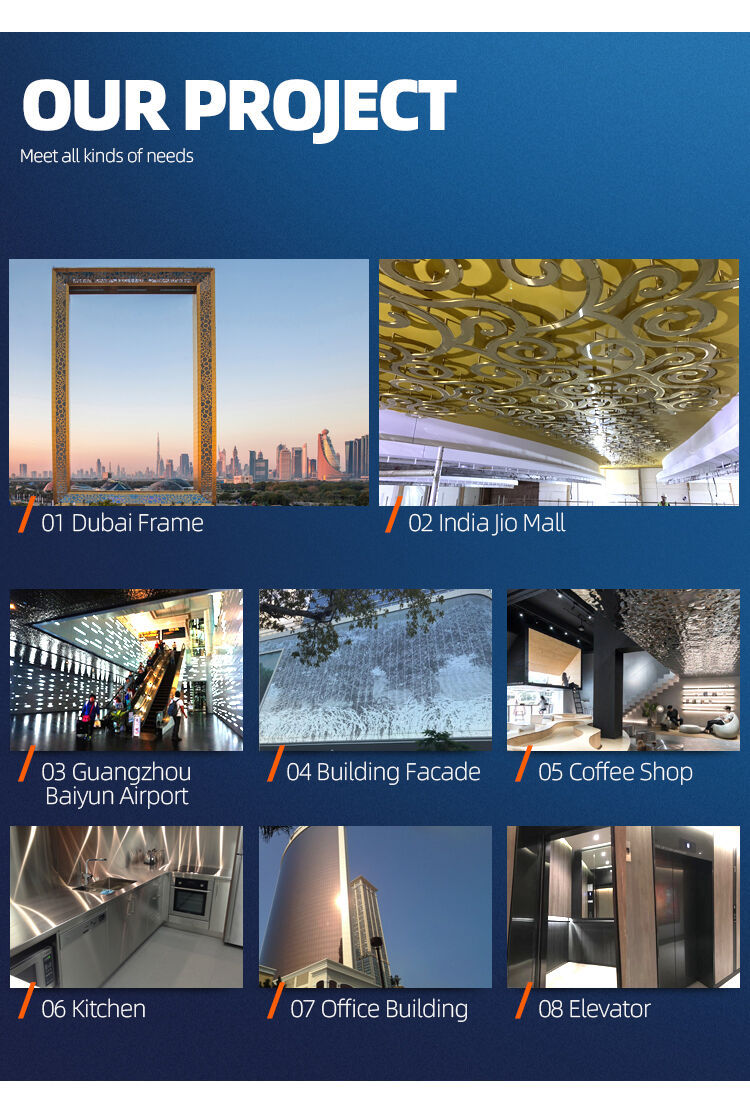

In recent years, stainless steel decorative plate have been used more and more widely because of its uniqueness. The decorative stainless steel plate not only has the unique and strength of metal, but also has various and constant color. Another important thing is, decorative stainless steel plate maintains the physical chemical and mechanical properties of primary color stainless steel, but also has stronger corrosion resistance than primary color stainless steel. This is why it has been widely used in the fields of buildings, chemical industries, automobile, electronics and arts since it came out in 1970s.

What can decorative stainless steel plates be used in?

Decorative stainless steel sheet is a very good decorative material. In the arts and craft industry, the colorful stainless steel is combined with etching and dot method can be used to produce 3D relief murals and hanging screens that will never fade. In addition, using colored stainless steel to make household appliances, cooking utensils,kitchen equipment and bathroom appliance will be deeply loved by consumers. In daily life, we also can see the use of black stainless steel plates to make solar collectors, and its selective heat absorption rate can reach 91%-93%.

How to classify decorative stainless steel plate?

1. By process

Ⅰ. Electroplate. The process of attaching a metal film to the surface of a metal or other material by electrolysis. It can prevent corrosion, improve wear resistance, reflectivity and enhance aesthetics.

Ⅱ. Water plating. It does not rely on an external power source in the aqueous solution, but relies on the reducing agent in the plating solution to carry out a chemical reduction reaction, so that the metal ions are continuously reduced on the autocatalytic surface to form a metal plating layer.

Ⅲ. Fluorocarbon paint . Coating with fluororesin as the main film-forming substance.

Ⅳ.Spray paint. Spray the paint into a mist with compressed air and apply it on the stainless steel plate to form different colors.

2. By surface treatment

A. Mirror

B. Hairline/brushed

C. Sandblasting

D. Etched

E. Embossing

F. Color coating

G. Checkered.

The above mentioned surface treatment methods, patterns and colors can be designed and selected by customers.

Features of decorative stainless steel sheet

Decorative stainless steel sheet is have widely used in decoration, It is decorated with elegant and luxurious quality. The colorful stainless steel plate also has strong corrosion resistance, high mechanical properties, long-lasting color surface layer, and color Different lighting angles will produce characteristics such as color changes.

One of the most popular grades 316L for #8 Mirror Sheet

316L stainless steel sheet #8 mirror has a non-directional finish that virtually looks like a mirror. 316L stainless steel sheet #8 mirror possesses a highly polished finish and does not contain or have a coating or finishing material to give it reflectivity. 316L stainless steel sheet #8 mirror comes with a double layer of PVC film to protect the mirror finish during fabrication and installation.

We offer value added fabrication to our 316L stainless steel #8 mirror, including hemming, laser cutting and corner rounding. We also manufacture trim molding and embossed sheets out of our 316L stainless steel #8 mirror sheets. The maximum thickness of 316L stainless steel #8 mirror sheet that we can hem is 22 gauge. If you need a bending option, please see our Angle/Channel section.

316L stainless steel sheet metal, also called marine grade stainless steel, is used primarily for its increased resistance to corrosion. The "L" means that the carbon content of the alloy is below 0.03% which makes the 316L stainless steel sheet preferable for welding. Uses for 316L stainless steel #8 mirror may include wall cladding, decorative commercial and residential stainless steel applications, outdoor applications, food grade applications, and any situation that high corrosion resistance is needed. 316L stainless steel sheet #8 finish is austenitic, meaning it will not attract or hold a magnet. If you need that option in stainless steel, the 430 grade will hold a magnet.

1.Special dimension was accepted on request

2. Customized specific cut-to-length are acceptable

3. PE/Laser PE/Optic fiber laser are available on request

4. Production details as following:

GET IN TOUCH

“Sufficient resources,fast delivery,high-quality package,customized according to drawings,after-sales intimate” is our service tenet,our goal is to satisfy every customer.We adhere to mutual benefit and win-win, develop and grow together.

We are looking forward to your inquiry and thank you for every order!