PRODUCTS

HOME > PRODUCTS

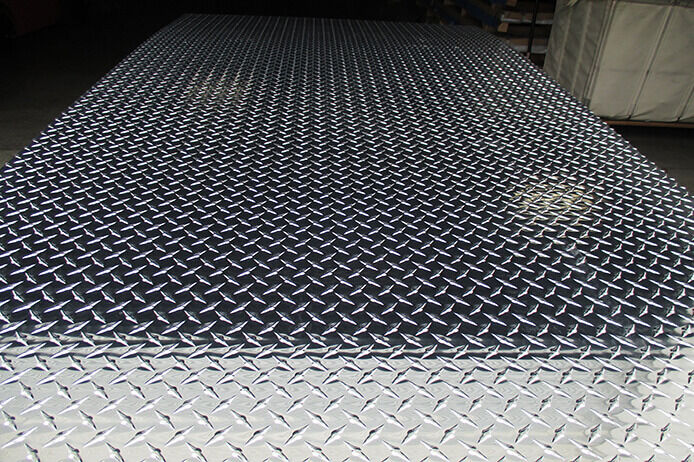

Thickness:0.2mm~12.0mm

Width:600mm-2650mm or customize

Standard: GB/T3880.2–2006

Characteristics:

1100 aluminum is a 1000-series aluminum alloy: it is considered commercially pure and is formulated for primary forming into wrought products.1100 is the Aluminum Association (AA) designation for this material. In European standards, it will be given a EN AW-1100. A91100 is the UNS number. Additionally, the EN chemical designation is Al99,0Cu.

We can provide full series of aluminum products, 1000 series, 2000 series, 3000 series, 5000 series, 6000 series, 7000 series, 8000 seires. Welcome to contact us, we will quote you a reasonable price.

Chemical Composition

Mechanical Properties

Thermal Properties

Application:

Manufature of railroad tank cars

Chemical Equipment

Common Caculations

Variations

1.1100-H112 Aluminum

1100-H112 is 1100 aluminum in the H112 temper. This temper is actually just a variation on F (as-fabricated) that allows for the possibility of very limited strain hardening or heat treatment, under certain conditions.

It has the second lowest strength and second highest ductility compared to the other variants of 1100 aluminum.

2.1100-H113 Aluminum

1100-H113 is 1100 aluminum in the H113 temper. This temper is a very specific variation on H112 that only applies to standard tube products.

It has the lowest strength compared to the other variants of 1100 aluminum.

3.1100-H12 Aluminum

1100-H12 aluminum is 1100 aluminum in the H12 temper. To achieve this temper, this metal is strain hardened to a strength that is roughly a quarter of the way between annealed(O) and full -hard (H18).

4.1100-H14 Aluminum

1100-H14 aluminum is 1100 aluminum in the H14 temper. To achieve this temper, this metal is strain hardened to a strength that is roughly a quarter of the way between annealed(O) and full -hard (H18).

5.1100-H16 Aluminum

1100-H16 aluminum is 1100 aluminum in the H16 temper. To achieve this temper, this metal is strain hardened to a strength that is roughly 3/4 of the way between annealed(O) and full -hard (H18).

6.1100-H18 Aluminum

1100-H18 aluminum is 1100 aluminum in the H18 temper. This is the strongest temper normally produced through the action of only strain hardening.

7.1100-H22 Aluminum

1100-H22 aluminum is 1100 aluminum in the H22 temper. To achieve this temper, this metal is strain hardened,and then partially annealed, to a strength that is roughly a quarter of the way between annealed(O) and full -hard (H28).

8.1100-H24 Aluminum

1100-H24 aluminum is 1100 aluminum in the H24 temper. To achieve this temper, this metal is strain hardened,and then partially annealed, to a strength that is roughly halfway between annealed(O) and full -hard (H28).

9.1100-H26 Aluminum

1100-H26 aluminum is 1100 aluminum in the H26 temper. To achieve this temper, this metal is strain hardened,and then partially annealed, to a strength that is roughly 3/4 of the way between annealed(O) and full -hard (H28).

It has the second lowest ductility compared to the other variants of 1100 aluminum.

10.1100-H28 Aluminum

1100-H28 aluminum is 1100 aluminum in the H 28 temper. This is the strongest temper normally produced through the action of strain hardening followed by partial annealing. It is closely related to related H18. It has the lowest ductility compared to the other variants of 1100 aluminum.

11.1100-O Aluminum

1100-O aluminum is 1100 aluminum in the annealed condition. It has the highest ductility compared to the other variants of 1100 aluminum.

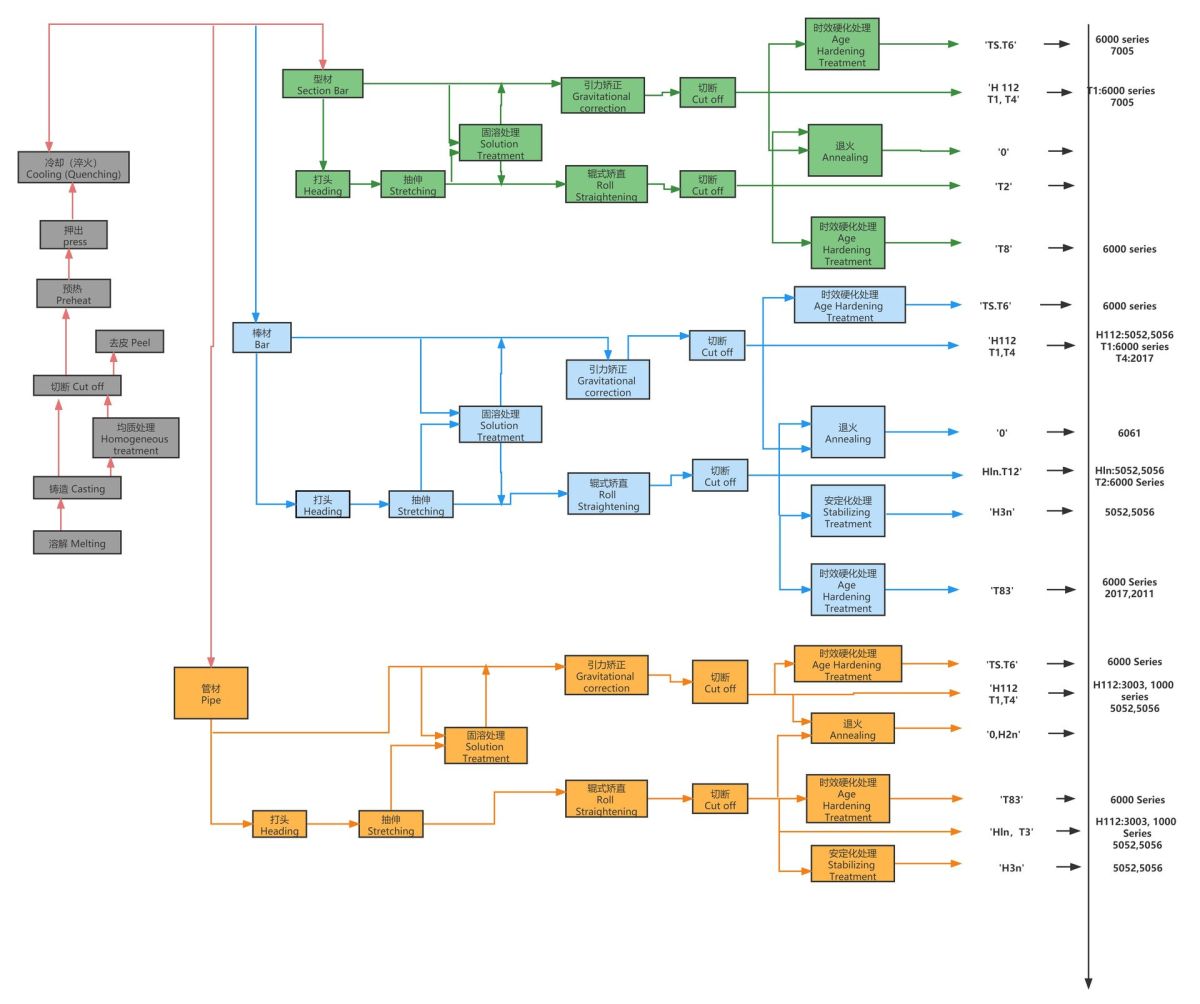

Process Flow

FAQ

1. Q:Are you a manufacturer or trading company?

A: We are a manufacturer, can do OEM and ODM.

2. Q: Can i get some samples? What product information do i need to provide?

A: Yes, we have small samples, like A4 size. You need to provide the grade (ALLOY NUMBER) and temper, thickness, width,length and the quantity.

3. Q: How does your factory do regarding quality control?

A: Quality is priority. Our factory has gained SGS authentication. We guarantee the goods out form our factory 100% qualified. And each process, we have very strict operation and arrange 2 technicians to inspect. After the products are finished, we will make the last test to pick up the unqualified products.

4. Q:What is your payment?

A: Generally we accept 30% T/T as deposit and 70% against with B/L copy

Packing & Shipping

GET IN TOUCH

“Sufficient resources,fast delivery,high-quality package,customized according to drawings,after-sales intimate” is our service tenet,our goal is to satisfy every customer.We adhere to mutual benefit and win-win, develop and grow together.

We are looking forward to your inquiry and thank you for every order!